Custom Specimens and Mock-ups

Custom Specimens and Mock-ups

Specialised training and qualification

Sonaspection products can be used for specific NDE training, procedure development, personnel training and qualification, specialists training and performance demonstration

- Advanced training and qualifications (Performance Demonstrations)

- Flaw detection

- Flaw sizing

- Complex weld geometries

- Exotic materials

- Equipment, procedures and personnel

Custom specimens are supplied with documentation which clearly identifies the flaw types, sizes and locations (flaw truth).

All specimens are supplied with as a minimum:-

- As built CAD drawing

- Flaw size statement optional

- Flaw photographs

- Flaw tracings

- Inspection reports

- Material certificates

- Certificate of conformance

Specimen types

- Ferritic pipes

- Austenitic pipes

- Dissimilar weld metals

- Weld overlay specimens

- Reactor vessel & nozzles

- Core shroud & spray specimens

- Pressuriser mock-ups

- CRDM mock-ups

- Bolting & studs

- Erosion/Corrosion

Ideal for NDE training and PDI qualifications.

| Dimension | Working | Final/reported |

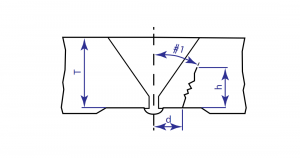

| Flaw Length (L) | ± 4mm(0.16″) | ± 1.5mm (0.06″) |

| Flaw Height (h) | ± 1.5mm(0.06″) | ± 0.75mm (0.03″) |

| From Weld Centre (d) | ± 1mm(0.04″) | ± 0.5mm (0.02″) |

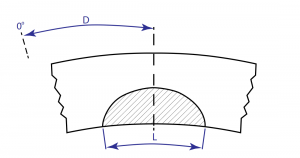

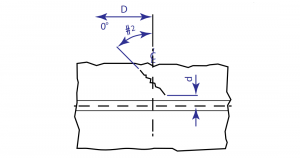

| From Pipe Datum (D) | ± 2mm(0.08″) | ± 1mm (0.04″) |

| Tilt (#1) | ± 5° | ± 5° |

| Skew (#2) | ± 5° | ± 5° |

|

||